proudly serving

the mid-south

Summer Prep for Refrigeration Systems Tips to Keep Your Cooling Efficient and Trouble-Free

When summer heat rolls into Memphis, your refrigeration systems have to hustle to keep your business on track. Getting your refrigeration ready for summer isn’t just a suggestion—it’s a must if you want to dodge breakdowns, keep cooling steady, and protect your inventory when things are busiest.

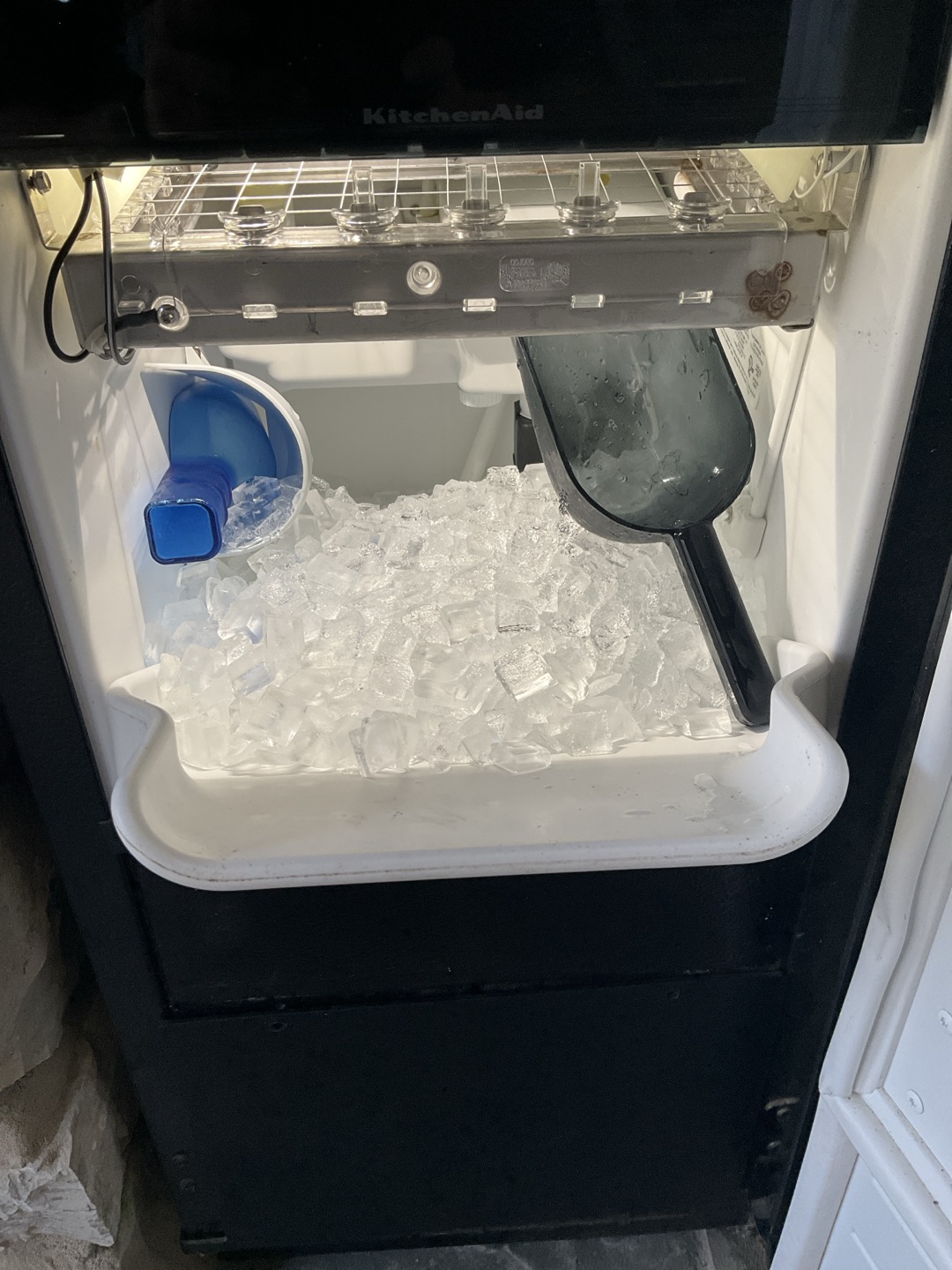

Your ice machines and walk-in coolers really depend on regular maintenance to handle the extra demand. We’ve been helping Memphis businesses tackle these summer challenges since 1977, and honestly, it’s all about making sure your equipment doesn’t let you down when the heat is relentless.

A little time spent checking water pressure, cleaning up key parts, and setting a maintenance schedule now will almost always save you headaches (and cash) later. With the right prep, you’ll keep things cool and efficient all summer.

Why Summer Prep Matters for Refrigeration Systems

Keeping your refrigeration running strong through summer means you need to think about how heat impacts your gear, how to head off breakdowns, and ways to make your system last longer. These steps help you avoid costly repairs and keep things cool when you need it most.

Impact of High Temperatures on Efficiency

High temps force your refrigeration system to work overtime. When the air around the unit heats up, parts like compressors and coils burn more energy just to hold the right temperature.

This extra effort can spike your electricity bill and slow down cooling. For instance, a walk-in cooler with dirty coils or worn-out door seals will lose cold air fast, so the system just keeps chugging. That wears stuff out and can spoil food.

Check things like coil cleanliness and door seals to keep your system efficient. At Memphis Ice, we make sure your equipment can handle those sticky Memphis summers without draining energy or breaking down.

Avoiding Costly Breakdowns

If you skip summer prep, your refrigeration gear could quit when you need it most. A busted ice machine or cooler means delays, lost sales, and wasted food—never fun, especially during a sweltering Mid-South summer.

Routine maintenance spots problems before they turn into emergencies. Cleaning coils, checking refrigerant, and inspecting electrical parts all lower your risk of sudden repairs.

With regular service, you sidestep expensive downtime. Planning ahead beats scrambling for urgent fixes. We’ve seen it over and over—catch issues early and you’ll save yourself a ton of stress.

Extending Equipment Lifespan

Proper summer prep isn’t just about surviving the season—it helps your equipment last longer. Heat and heavy use really age parts, leading to more replacements.

Simple stuff like cleaning coils, checking seals, and keeping ice machines tidy cuts down on wear. That keeps your refrigeration from overworking. When things run smoothly, you can put off those big upgrades.

If you want fewer headaches and better performance, regular prep is the way to go. We’re here to help keep your business cool, whatever the weather throws at you.

Essential Pre-Summer Inspection Checklist

Getting your refrigeration system ready for summer? Focus on the basics: coolant level, working electricals, accurate thermostat, and clear airflow. Each step helps you avoid trouble when temperatures soar.

Checking Refrigerant Levels

Refrigerant keeps things cold. If you’re low, the equipment strains, which means breakdowns and higher bills. First, check for leaks—losing refrigerant means lousy cooling and isn’t great for the environment.

Use gauges to measure pressure and compare it to what the manufacturer says. If you’re low, get a pro to handle it. Seriously, don’t DIY refrigerant—leave it to certified techs like ours.

With proper refrigerant, your ice machine or walk-in cooler stays reliable, even when Memphis turns into a sauna.

Examining Electrical Components

The wiring, fuses, contactors, and relays in your system can get cranky in the heat. Switch off the power, then look for cracked or frayed wires.

Use a multimeter to check voltage and current, especially for the compressor and fans. Swap out anything that’s looking worn before things heat up—you’ll thank yourself later.

A quick electrical check now can save you from downtime and big repair bills down the road.

Verifying Thermostat Accuracy

If your thermostat is off, even a little, your system won’t cool right. That means spoiled goods and frustrated customers. Compare its reading to a good digital thermometer inside the unit.

If it’s off, calibrate it (check the manual) or call a specialist. Make sure the sensor isn’t sitting near vents or lights that could mess with readings.

Getting the temperature right means better ice and safer food storage.

Ensuring Proper Airflow

Airflow keeps your refrigeration from overheating. Check grills, vents, and condenser coils for dust or blockages.

Clean coils with a soft brush or vacuum—don’t be rough, those fins bend easily. Keep outdoor units clear of plants and junk.

Fan blades should spin freely. If you spot a busted fan, swap it out. Good airflow cuts energy costs and helps equipment survive the summer.

We run into blocked airflow all the time—don’t let it trip you up.

Cleaning and Maintenance Tips

Keeping your refrigeration humming means regular cleaning and maintenance. Focus on coils, filters, and drain lines to keep the cold steady.

Cleaning Condenser and Evaporator Coils

Coils collect dirt and dust, making your system work harder. Dirty coils kill efficiency and jack up energy costs. Use a soft brush or vacuum to gently clear debris. If they’re really grimy, try a no-rinse coil cleaner.

Check coils at least twice a year, and definitely before summer. Don’t bend the fins—they need to stay straight for airflow. Clean coils mean steady temps and less overheating.

Replacing or Cleaning Air Filters

Air filters grab dust but clog up fast, especially in busy kitchens or stores. Blocked filters choke airflow, making your system struggle.

Replace disposable filters every 1–3 months, depending on how much you use them. Wash reusable ones monthly with warm water and mild soap. Dry them completely before putting them back. Clean filters help your system last longer and keep air quality up.

Clearing Drain Lines

Drain lines move away condensation and extra water. Over time, they fill up with algae, mold, or minerals. A clogged drain means leaks and possible water damage.

Flush drain lines every few months with warm water and vinegar (or a safe cleaner). Check that water flows freely each time you inspect. Quick drain care helps you avoid water messes and keeps your system draining right.

We’ve been keeping Memphis businesses cool since the ’70s, and a little regular cleaning makes a big difference when things get busy.

Optimizing System Performance Before Summer

Getting ready for summer isn’t just about cleaning—it’s about dialing in your system for top performance. Fine-tune controls, set the right temps, and balance the cooling load to keep everything chill when business heats up.

Calibrating System Controls

Start by checking if your thermostat and sensors are accurate. If readings are off, your system might overcool or undercool, wasting energy or risking spoiled goods.

Use a good thermometer to compare real temps to your controls. Adjust as needed, and reset controls if things seem off.

Look at timers and defrost cycles too. Defrosting keeps ice from building up and stressing compressors. In Memphis heat, you might need to run these cycles more often.

Setting Optimal Temperature Ranges

Set your units to protect products without wasting energy. Freezers usually work best between 0°F and 5°F; walk-in coolers, 35°F to 38°F.

Don’t set temps lower than needed—it just stresses the system and burns power. Check setpoints regularly and tweak them for the season or what you’re storing.

If you run too warm, you risk food safety. Too cold, you’re just paying extra. Find the right balance for longer equipment life.

Balancing Cooling Loads

Refrigeration works hardest with uneven loads. Spread out storage so air can move around. Don’t stack boxes too tight or block fans.

If you’ve got hot spots or heavy use, think about extra units or cooling power to even things out.

Regular maintenance helps spot load problems early, so you can avoid overworking parts or surprise breakdowns when things get busy.

Preventive Measures for Common Summer Issues

Summer heat adds extra stress to your refrigeration. Stay ahead by controlling temperature, listening for weird noises, and watching for leaks. These steps help you dodge bigger problems that could mess up your busiest months.

Preventing Overheating

Hot weather makes your units work harder. Keep condenser coils clean by clearing dust and debris often. Dirty coils mean hotter running, less efficiency, and more wear.

Give your unit space—don’t block vents or crowd equipment. Good ventilation keeps temperatures in check.

Watch refrigerant levels. Low refrigerant overheats compressors. If your system runs hot or keeps tripping breakers, call Memphis Ice for a checkup.

Addressing Unusual Noises

Odd sounds are your system’s way of waving a red flag. Listen for grinding, rattling, or hissing. These can point to loose parts, worn belts, or refrigerant leaks.

Tighten up any loose screws or bolts around fans and motors. Swap out cracked or stretched belts. If the noise sticks around, get a Memphis Ice tech to look before it turns into a real issue.

Lubricate moving parts to cut down on friction. If you hear banging or heavy vibrations, the compressor might be struggling—don’t wait to get it checked.

Monitoring for Leaks

Leaks sap cooling power and waste refrigerant, which hurts performance. Watch for frost around evaporators or puddles near compressors.

Check hoses and fittings every week during peak season. Small leaks are easier to fix than big ones that drain your system dry.

Use a leak detector or dab soapy water on joints—bubbles mean trouble. If you spot a leak, call your local experts right away. Quick action saves energy and money.

Energy Efficiency Upgrades for Hot Months

Running your refrigeration efficiently in the heat can really cut your energy bills. Upgrades and smart tech help you keep a close eye on things and run lean.

Installing Energy-Efficient Components

Switching to energy-efficient parts helps your system use less power and stay cooler. High-efficiency compressors and fans pull less energy. LED lights in coolers save electricity and make it easier to see what’s inside.

Better insulation for walk-ins keeps cold air in, warm air out, and cuts down on how often your system kicks on.

Change air and water filters regularly. Clean filters mean smoother operation and less wasted energy. We always suggest handling upgrades before the summer rush—waiting until it’s blazing hot is just asking for trouble.

Implementing Smart Monitoring Solutions

Smart monitoring devices keep tabs on your refrigeration system’s temperature, humidity, and energy use in real time. These tools send alerts if something’s off, so you can fix issues before they get expensive.

With remote monitoring, you can tweak settings on the fly—even if you’re nowhere near the building. That helps you avoid overheating or nasty power spikes, and you don’t have to wait around for a technician.

The data from these systems? Super useful. You can spot trends, plan maintenance, and catch inefficiencies early. A lot of Memphis businesses rely on Memphis Ice to set up and manage these smart solutions, especially when summer heat puts their cooling to the test.

Scheduling Professional Maintenance

Booking regular professional maintenance keeps your refrigeration system running smoothly all summer. It’s a way to catch problems early and avoid sudden breakdowns that can ruin your day.

Finding Qualified Technicians

Find technicians who know commercial refrigeration inside and out, especially those who’ve worked on ice machines and walk-in coolers. A solid technician checks key parts—condensers, refrigerant, filters—so you don’t end up with preventable issues.

Memphis Ice has been around since 1977, with a team that gets the needs of local businesses. Local know-how really matters here, since Memphis weather can be brutal on cooling equipment.

Look for companies that offer clear maintenance plans and quick emergency repairs. Good techs will keep your ice machine and refrigeration units humming, so you don’t lose time or money when it’s blazing outside.

Timing Your Maintenance Visits

Book your maintenance visits before the summer heat kicks in. Early service catches last year’s wear and tear, so you’re not left scrambling when things get busy. Go for a full cleaning of condenser coils, swap out water filters, and check refrigerant.

During summer, set up regular checkups to keep things efficient. Frequent inspections help you catch small stuff before it grows into a big headache. Memphis Ice can tailor maintenance plans to your schedule, whether you’re running a packed restaurant or a giant cold storage.

Timely visits cut down on energy use and help your equipment last longer. You won’t be panicking for emergency repairs when the temperature spikes, and your inventory stays safe.

Monitoring and Adjusting Usage Throughout Summer

Summer heat puts real pressure on your refrigeration and ice machines. To keep things steady, watch how your equipment performs during busy hours. Keep an eye on temperature and ice output—it’s easy to miss subtle changes if you’re not looking.

Adjust settings to save energy when you can. Maybe you drop cooling power during off-hours or when the place is empty. It’s a simple move, but it adds up in savings without risking your products.

Keep tabs on water pressure for your ice machine. Memphis Ice techs always mention this—it’s key for steady ice production. If pressure dips, your ice output will too, and that can hurt business.

Here’s a quick checklist to help you stay on track:

| Task | Frequency | Benefit |

| Check temperature settings | Weekly | Keeps food safe |

| Inspect ice machine output | Twice a week | Ensures steady supply |

| Adjust cooling off-hours | Monthly | Saves energy |

| Watch water pressure | Weekly | Maintains ice quality |

Regular monitoring puts you in control and helps avoid surprises. Memphis Ice has helped Mid-South businesses keep cool since 1977. Your systems should be ready for the summer rush, and making adjustments as you go is just part of the routine.

Building a Year-Round Maintenance Routine

Reliability doesn’t happen by accident—you need a year-round maintenance plan to dodge surprise breakdowns and keep things running right.

Start with a full service at least once a year, preferably before it gets hot. If your system works hard all year, check it more often. That way, you’ll catch little problems before they snowball.

Regular tasks? Clean the coils, check refrigerant, inspect fans and seals. Don’t skip the ice machine—keep it clean and tuned. Good airflow matters as much as the mechanical stuff.

Here’s a basic checklist:

- Clean condenser coils every 3-6 months

- Check refrigerant and electrical connections quarterly

- Inspect door gaskets and seals monthly

- Schedule pro tune-ups annually

At Memphis Ice, we’ve kept Mid-South businesses cool since 1977. Our team puts together maintenance plans that actually fit your operation and the local climate.

Having a routine takes the stress out of summer. Your refrigeration system will be ready for whatever comes—busy restaurants, hospitals, you name it. You’ll save money, keep your stock safe, and avoid those frantic repair calls.

Reach out to an expert and set up a plan that works for your business and Memphis weather.

Frequently Asked Questions

Getting ready for summer means focusing on regular service, checking key parts, and making smart energy tweaks. Spotting warning signs early helps you avoid breakdowns when the heat’s on.

How often should I service my refrigeration system before summer hits?

Have your refrigeration system checked at least once before summer. If your kitchen or ice machine stays busy, twice a year makes more sense.

What are the top maintenance tips to keep my fridge running smoothly in the heat?

Clean condenser coils often. Replace old gaskets and check door seals. Make sure nothing blocks airflow around the unit.

Are there specific components I should check when preparing my refrigerator for summer?

Check the condenser coils, evaporator fan, and door seals. Confirm refrigerant levels and look for leaks or odd noises.

Can you recommend a checklist for summer-prepping my commercial refrigeration units?

- Clean condenser coils.

- Check and replace door gaskets if needed.

- Inspect fans and motors for smooth running.

- Test temperature controls.

- Verify refrigerant levels.

- Remove any ice buildup in the evaporator.

What signs indicate that my refrigeration system isn’t ready for the summer season?

If your fridge feels warmer than usual, makes weird sounds, or has moisture leaks, those are warning signs. Reduced ice production is another big clue.

How can I improve the energy efficiency of my refrigeration system during the warmer months?

Try keeping the coils clean—dust and grime make your fridge work harder than it should. Don’t cram too much inside, and, yeah, resist the urge to stand there with the door open. It helps more than you’d think. Timers or energy-saving settings can make a real difference too, if your system has them.

Memphis Ice has been around the Mid-South, helping folks with this stuff since 1977. If you’re not sure where to start, maybe just ask an expert and see if your equipment’s up to the job.

Recent News

Best Maintenance Tips for Bar Refrigeration Systems to Keep Your Drinks Cold and Equipment Running Smoothly

Benefits of Working with Certified Refrigeration Technicians for Reliable and Efficient Cooling Solutions

Walk-In Freezer Organization Tips for a Cleaner, More Efficient Space

What Impacts Ice Machine Performance In Humid Climates Friendly Tips To Keep It Running Smoothly

Benefits of Routine Walk-In Cooler Maintenance for Restaurants to Save Money and Improve Efficiency

Ringing in the New Year: The Best Drinks Start with the Best Ice